Technology doesn’t last forever. Every device eventually reaches End-of-Life (EOL), and when this stage is poorly managed, organizations can face security vulnerabilities, unexpected costs, and operational friction. End-of-Life equipment is therefore not just a technical milestone, but a management challenge IT teams cannot ignore.

In this article, we’ll explore what qualifies as End-of-Life equipment, why it matters for organizations, and how to build a strategy that allows IT teams to handle these assets without introducing unnecessary risk, cost, or disruption.

What is end-of-life equipment?

End-of-Life equipment (sometimes called End-of-Life hardware) refers to devices that have entered the phase where the model is being retired from the manufacturer’s portfolio. This stage is typically associated with declining availability, fewer updates, and a gradual reduction of vendor support activities.

Does this mean the device must be replaced immediately? Not necessarily. Many End-of-Life assets continue to operate without short-term issues. However, as updates and manufacturer support diminish over time, organizations may face increasing risks related to security, compatibility, and long-term maintainability.

Hardware lifecycle terminology explained: GA vs. EOD vs. EOL vs. EOSL

Hardware manufacturers use several terms to describe the different stages of a product’s lifecycle. Although these labels are widely used, they are often misunderstood or treated as equivalent, which can lead to poor planning and unnecessary risk.

Here are the most important distinctions:

- General Availability (GA) – The product is officially released and fully supported. The manufacturer actively produces, sells, updates, and maintains the device. Firmware updates, spare parts, replacements, and support contracts are all typically available.

- End of Development (EOD) – The manufacturer stops advancing the product’s software or firmware. No new features or enhancements are introduced, though maintenance services and limited support may still exist. The device remains usable but becomes technologically static.

- End of Life (EOL) – The hardware model is phased out of the vendor’s portfolio. Production or sales of new units usually stop, updates become less frequent, and vendor focus shifts to newer products. EOL does not necessarily mean immediate obsolescence, but it signals increasing lifecycle risk.

- End of Service Life (EOSL) – Sometimes referred to as End of Support (EOS), this marks the final support milestone. The manufacturer fully discontinues maintenance, updates, repairs, and technical assistance. Organizations must rely on third-party maintenance or replace the equipment.

Understanding these lifecycle stages is essential for Hardware Asset Management teams, as each milestone affects risk exposure, budgeting decisions, security posture, and long-term operational stability.

| Lifecycle stage | EOD | EOL | EOSL |

| What does it mean? | The manufacturer stops delivering enhancements or new features. The device becomes technologically static. | The hardware model is phased out of the vendor’s portfolio. Production or sales typically stop. | The manufacturer fully discontinues maintenance, updates, and technical support. |

| Availability | Hardware may still be available, though innovation and updates cease. | New units become difficult to obtain. Spare parts may become scarce or more expensive. | Official channels no longer provide units or components. Secondary markets may be the only source. |

| Implications for users | Devices remain functional but receive no new capabilities or feature improvements. | Devices remain usable, but vendor attention, updates, and prioritization decline. | Continued use introduces reliability concerns, security exposure, and operational uncertainty. |

| Support | Limited support may continue, often restricted to maintenance or critical fixes. | Reduced or selective support depending on vendor policies. | No manufacturer support, updates, or repair services are provided. |

| Impact on business | Gradual increase in technological limitations and potential compatibility constraints. | Increased security, financial, and operational risks as availability and support diminish. | Highest risk exposure, including security vulnerabilities, compliance issues, and potential failures. |

| Recommendation | Evaluate long-term viability and begin considering refresh strategies for critical assets. | Actively plan replacements or implement risk mitigation strategies. | Replace the equipment or adopt validated third-party maintenance while managing associated risks. |

What to track in your inventory

Understanding lifecycle terminology is important, but its real value comes from how this information is reflected in your asset inventory. Rather than tracking every possible vendor milestone, organizations should prioritize a small set of fields that directly influence risk, supportability, and planning decisions.

Key data points include the asset model, assigned owner, warranty or support end date, official EOL or EOSL dates, and the current lifecycle status. These attributes allow IT teams to anticipate refresh cycles, detect emerging risks, and avoid reactive replacement strategies.

Why is end-of-life equipment important?

Understanding and tracking your EOL hardware is essential. Here's why keeping an eye on your End-of-Life equipment can greatly benefit your IT team and organization overall:

1. Improved security

End-of-Life hardware is exposed to vulnerabilities. Tracking EOL dates allows IT teams to replace or secure devices before they introduce avoidable risk. Ignoring this stage often results in unnoticed security gaps.

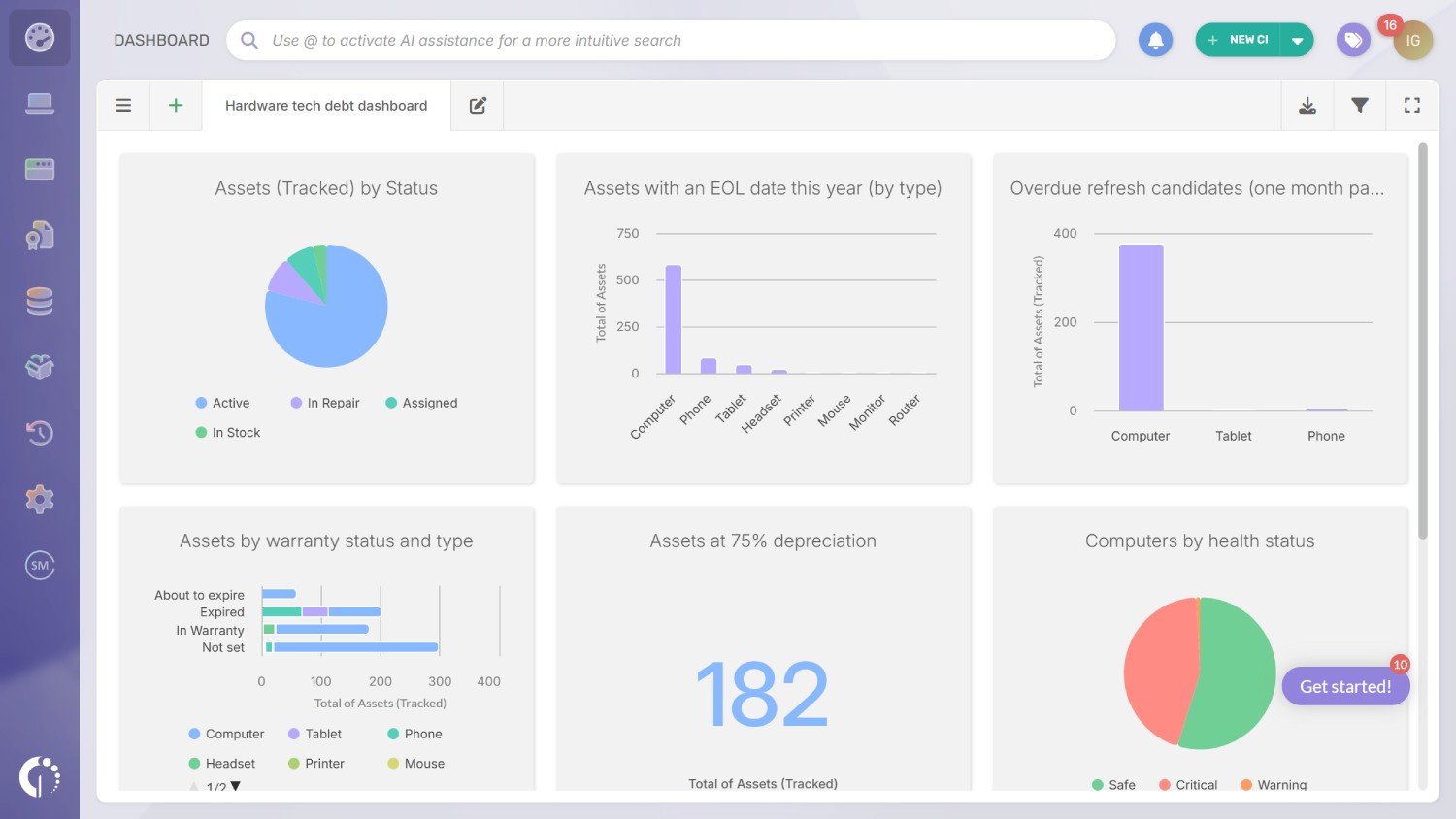

InvGate Asset Management supports lifecycle risk visibility by enabling teams to create custom fields for critical milestones such as End-of-Life and End-of-Support dates. These attributes can be combined with automation rules that alert teams as deadlines approach, helping prevent unsupported devices from remaining in active environments.

2. Reduced maintenance costs

Older hardware typically becomes more expensive to maintain and harder to support. Visibility into lifecycle stages helps teams avoid reactive repairs and unplanned downtime. Poor lifecycle control often leads to escalating costs and operational friction.

InvGate Asset Management helps organizations stay ahead of these risks through its depreciation capabilities, which allow teams to track how assets lose value over time. Alerts can be configured to flag devices reaching defined thresholds, supporting more informed repair or replacement decisions. Maintenance activities can also be organized using custom fields, improving oversight of service schedules, particularly for high-touch assets.

3. Better budget planning

Clear visibility into EOL timelines helps organizations forecast refresh cycles and avoid reactive spending. When lifecycle milestones are not tracked, hardware replacements often become urgent and disruptive. This reduces financial predictability and strains IT planning.

InvGate Asset Management supports more accurate budgeting by providing structured lifecycle data and financial context. Capabilities such as depreciation tracking, health rules, and customizable asset attributes help teams anticipate replacement needs. This visibility enables more realistic hardware refresh plans and reduces the likelihood of budget shocks caused by unexpected asset conditions.

4. Enhanced compliance

Many regulations and internal policies require supported and up-to-date hardware. Tracking EOL milestones helps organizations reduce compliance risks and maintain governance over their asset environment. Poor lifecycle visibility can lead to audit issues and control gaps.

InvGate Asset Management strengthens compliance by combining lifecycle tracking with asset traceability. In addition to monitoring key dates such as End-of-Life and End-of-Support, teams can review the chain of custody of each asset, preserving a historical record of assignments and status changes. This level of visibility helps organizations demonstrate control and reduces the risk of discrepancies caused by incomplete asset data.

5. Increased operational efficiency

Proactive Hardware Lifecycle Management reduces the risk of unexpected device failures and compatibility issues. This supports higher uptime, more stable environments, and smoother IT operations. Poor lifecycle oversight often results in avoidable outages, degraded performance, and reactive firefighting.

For example, reactive environments often deal with sudden device failures that disrupt users and require urgent intervention. In contrast, proactive teams replace or service assets based on lifecycle data, avoiding unplanned downtime and service interruptions.

How to manage EOL equipment successfully?

Managing End-of-Life equipment effectively is crucial for maintaining secure and reliable IT operations. Here are practical steps and best practices your team can implement to handle EOL hardware proactively:

1. Create and maintain a hardware inventory

Creating and regularly updating an inventory of your IT assets gives your team full visibility into the equipment lifecycle, including when devices reach their EOL dates. Clearly document model numbers, purchase dates, and current software versions to stay organized and informed.

InvGate Asset Management enables teams to build a unified IT asset inventory that covers not only hardware, but also software and other IT assets. Inventory data can be populated through multiple mechanisms, including manual entry, network discovery, agent-based collection, and integrations. Hardware assets are automatically recorded with their relevant attributes and processed through data normalization, helping maintain a structured, consistent, and reliable inventory over time.

2. Keep an eye on manufacturer notifications

Manufacturers typically send alerts via email well before equipment reaches EOL. Ensure these notifications don't go unnoticed by designating someone on your IT team to monitor and act on these updates promptly.

InvGate Asset Management allows teams to extend asset records using custom fields, making it easier to track vendor-specific attributes or lifecycle data that may not be included by default. Additionally, InvGate is developing Atlas, an AI-driven feature designed to automatically retrieve lifecycle and vendor data from manufacturer sources. By capturing information such as End-of-Life and End-of-Support dates without manual intervention, Atlas helps organizations maintain reliable asset intelligence and reduce the risk of outdated lifecycle records.

3. Assess the status and prioritize replacements

Not all End-of-Life devices introduce the same level of urgency. Replacement decisions should consider both lifecycle milestones and the operational condition of each asset. Establishing clear prioritization criteria helps IT teams focus on hardware that presents the highest risk or business impact.

Not all End-of-Life devices introduce the same level of urgency. Replacement decisions should consider both lifecycle milestones and the operational condition of each asset. Establishing clear prioritization criteria helps IT teams focus on hardware that presents the highest risk or business impact.

We support this process through InvGate Asset Management's Smart Tags, which can automatically classify assets based on lifecycle attributes such as approaching or exceeded EOL dates. In addition, Health Rules allow teams to define technical and security-related conditions, including disk capacity, firewall presence, or pending operating system updates. Together, these mechanisms help organizations design more informed hardware refresh plans driven by real asset data rather than static timelines alone.

4. Set a realistic and strategic budget

Forecasting hardware replacements based on lifecycle assessments helps organizations avoid disruptive spending and maintain financial predictability. Aligning refresh cycles with budget planning reduces the likelihood of emergency procurement and reactive investment decisions.

InvGate Asset Management supports this process through its depreciation capabilities, allowing teams to track how asset value changes over time. This financial context, combined with lifecycle visibility, helps organizations justify replacement decisions and prioritize investments. Reporting tools further assist by providing clear insights into asset conditions, upcoming needs, and budget-impacting trends.

5. Establish a clear hardware refresh plan

Defining a structured hardware refresh plan helps organizations reduce lifecycle risks, improve stability, and avoid reactive replacement cycles. A well-designed plan ensures that aging assets are addressed systematically rather than only when failures occur.

Defining a structured hardware refresh plan helps organizations reduce lifecycle risks, improve stability, and avoid reactive replacement cycles. A well-designed plan ensures that aging assets are addressed systematically rather than only when failures occur.

A simple refresh workflow typically includes:

- Planning – Identify upcoming lifecycle milestones and replacement needs.

- Procurement or acquisition – Align purchasing decisions with technical and financial criteria.

- Deployment – Introduce new assets without disrupting existing operations.

- Operation and maintenance – Monitor performance, health, and support status over time.

- Retirement and disposal – Safely decommission obsolete or unsupported devices.

InvGate Asset Management supports these workflows by centralizing lifecycle data, asset status, and decision-driving attributes. This visibility through dashboards and charts helps teams coordinate refresh activities, maintain consistency, and reduce gaps across hardware transitions.

6. Rely on internal or external IT expertise

Managing End-of-Life equipment is not purely a technical task. Effective lifecycle decisions require coordination across multiple stakeholders to balance operational, financial, and security considerations. Clearly defined responsibilities help prevent delays, misalignment, and reactive outcomes.

Typical governance models involve roles such as the IT asset owner, procurement teams, security leaders, and finance stakeholders. While IT may identify lifecycle risks or replacement needs, procurement evaluates sourcing options, security assesses exposure, and finance validates budget impact. This shared accountability structure ensures that refresh and retirement decisions are both timely and strategically aligned.

Simplify your EOL management with IT Asset Management software

Managing End-of-Life equipment becomes significantly more effective when lifecycle data, asset conditions, and financial context are centralized within an IT Asset Management platform. Rather than reacting to isolated vendor notifications or unexpected failures, organizations can rely on continuously updated asset intelligence.

InvGate Asset Management provides the structural foundation required for EOL management. By combining unified inventory capabilities, lifecycle controls, and automation mechanisms, teams can:

- Maintain a normalized, continuously updated inventory populated through discovery, agent-based collection, manual entry, and integrations.

- Track vendor-specific attributes and lifecycle milestones using custom fields and automated alerts.

- Identify aging or at-risk assets through Smart Tags and Health Rules based on technical and security conditions.

- Monitor depreciation trends to support budgeting, refresh planning, and replacement justification.

- Preserve asset traceability through lifecycle tracking and chain of custody records.

- Coordinate hardware refresh workflows by integrating with InvGate Service Management.

These capabilities allow organizations to shift from reactive management to a model driven by visibility, risk awareness, and structured decision-making.

InvGate Asset Management helps teams stay ahead of lifecycle risks while keeping IT operations stable and predictable. Start your 30-day free trial and see how much easier End-of-Life equipment management becomes with the right asset intelligence foundation.

In conclusion

Managing End-of-Life equipment requires more than simply reacting to vendor timelines. It demands continuous lifecycle visibility, structured decision-making, and alignment between operational, financial, and risk considerations. Organizations that understand the implications of EOL, EOD, and EOSL stages are better positioned to prevent disruptions, control costs, and maintain a stable IT environment.

IT Asset Management software plays a critical role in enabling this approach by transforming asset data into actionable lifecycle intelligence, helping teams anticipate change instead of responding to failure.