If you’re part of an IT team, you know losing track of an IT asset can quickly turn into a nightmare. It’s not just about the cost or the lost productivity, it’s also about the security stress that comes with it, and the potential risk of data exposure.

That’s why effective asset tracking is a key part of IT Asset Management (ITAM). And while there are multiple ways to achieve this goal (often used in combination), one of the most practical and widely adopted methods is using QR codes for ITAM.

QR codes don’t just assign a unique identifier to each IT asset, they also give your team fast, easy access to the asset’s key information. The result: a more accurate inventory that stays up to date and accessible whenever you need it.

In this article, we’ll show you how to create QR codes to track, monitor, and manage assets using InvGate Asset Management.

Why do you need QR code inventory tracking?

Losing track of an IT asset, not knowing where it is, who’s using it, or when it was last serviced can get expensive fast. And it’s not just a financial issue. It impacts day-to-day productivity, increases cybersecurity exposure, and can create compliance gaps that are hard to justify during audits.

That’s where QR code inventory tracking makes a real difference. QR codes help prevent these situations (or keep them from escalating) by enabling two key things: full visibility into your IT resources and instant access to accurate asset information whenever someone needs it.

In most cases, this is powered by specialized IT Asset Management software that not only generates QR codes, but also centralizes, monitors, and keeps each asset record updated, turning asset tracking into a reliable, scalable process.

QR codes vs barcodes vs RFID: key differences

Using QR codes for asset tracking is a flexible, cost-effective option because they can store more data than barcodes and link directly to detailed asset records. They can be scanned with any smartphone, which makes them easy to deploy across teams without extra hardware. For most IT environments, they offer the best balance between simplicity, visibility, and usability.

Barcodes are a simpler alternative, mainly designed for basic identification rather than detailed tracking. They usually contain limited information and require dedicated scanners, which reduces flexibility in day-to-day IT operations. They work well for straightforward inventory lists, but they fall short when you need richer asset context.

RFID tags are built for speed and automation, as they can be read in bulk without line of sight and are highly durable. They’re ideal for high-volume environments where assets move constantly, but they require specialized readers and a higher upfront investment.

Using InvGate Asset Management as your QR code tracking software

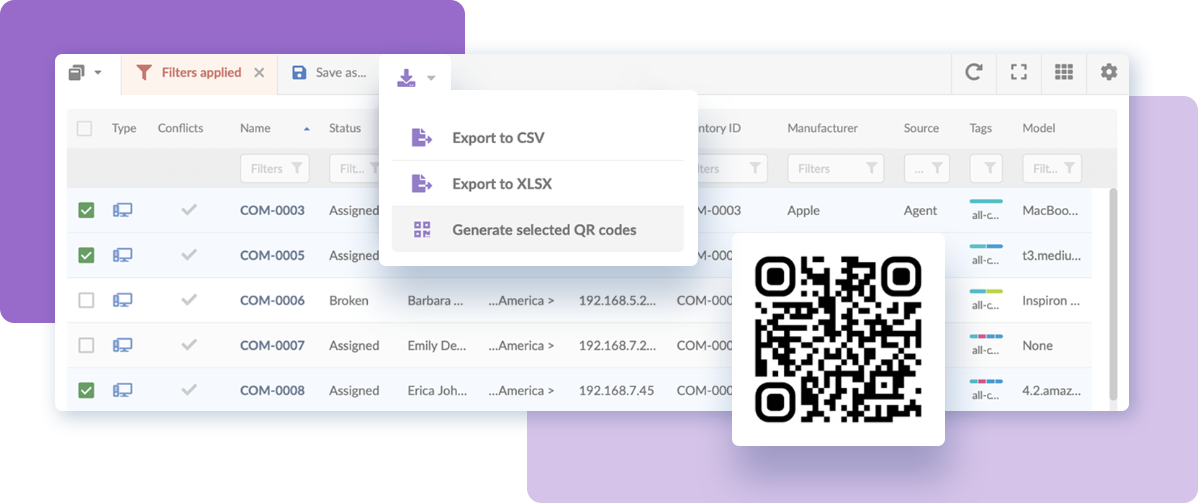

InvGate Asset Management makes it easy to track assets using QR codes. Whether you're managing IT devices, tools, or non-IT equipment, the platform gives you everything you need to generate, print, and use QR code asset tags at scale - making it a powerful and flexible QR code tracking software.

Here’s what you can do with InvGate Asset Management:

- Create an IT asset inventory – Create your IT inventory in no time using our multiple data population methods.

- Customize your asset records – Add custom fields, attachments, warranty details, locations, and more to support IT asset tagging and enrich each asset’s profile, making your QR codes truly useful.

- Generate QR codes in seconds – Select one or multiple assets, export the QR codes as a printable document or CSV, and choose label settings (including thermal printer format and optional asset numbers).

- Print and apply QR labels – Once exported, print and affix the QR code labels directly to your assets for quick identification and access. This step is particularly useful for hardware tracking.

- Scan on the go with the mobile app – Teams can scan QR codes in the field to instantly open the full asset profile and access real-time details like specs, status, and history. From the same app, they can also update, verify, and audit assets without needing extra hardware.

Ready to simplify your asset tracking process? Start your 30-day free trial of InvGate Asset Management today and experience how seamless QR code Asset Management can be.