No matter just how well things are going, there is always room for improvement. This applies to your organization as well as to just about everything in life. Process improvement is the practice of identifying and enhancing business processes in order to fight redundancies, optimize performance and productivity, increase profits, and create better user experiences.

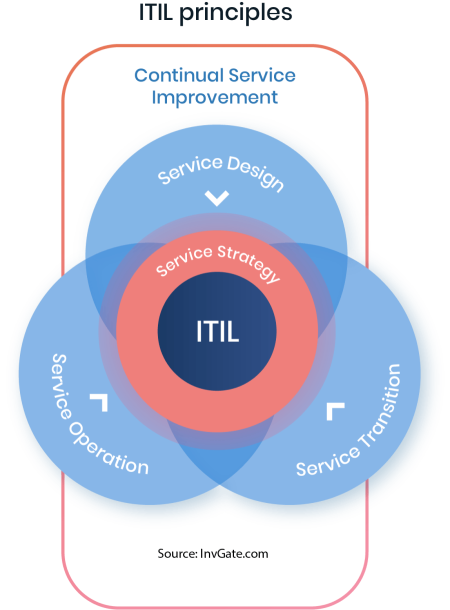

As part of the ITIL practice, it seeks to analyze the organization's business processes to identify areas where they can improve accuracy, effectiveness and efficiency. Changes are then made within the processes to accomplish these improvements. It also uses principles of ITSM (IT Service Management) as well as capabilities in IT and other business areas to improve operations, experiences, outcomes, and services.

5 benefits of Process Improvement

Every company relies on different business processes to perform their activities, which include a great variety of tasks: from selling products or solving IT problems to receiving payments.

Each activity has a process behind; that is why it's so important to streamline processes, by making sure there are no inconsistencies, redundancies, fewer resources or anything that could lead to lack of efficiency which, in turn, will result in great money loss.

Inefficiency costs companies between 20% to 30% of their revenue every year, according to research firm IDC. A strong business process management is crucial to avoid these problems.

Process improvement projects can lead to the following benefits:

- Better results. Improvements will result in better performance and more streamlined tasks.

- Time well spent. Business process improvement helps reduce time to complete tasks as it may decrease the number of people involved in a task, for example, by including automation.

- Greater profits. Streamlining processes and achieving better efficiency leads to fewer losses and eventually to increased profits for the company.

- Clear communication. One important aspect of process improvement is communication. When steps are clearly stated, employees will better understand what to do and how to do it. Responsibilities should be clearly pointed out, so that everyone knows what's expected of them and the steps to be carried out in order to achieve the objectives set. This is part of any process improvement.

- Client satisfaction. Better response time, more streamlined processes, fewer mistakes will definitely lead to major client satisfaction.

Business processes examples: 7 problems or inefficiencies to look for

- Duplication of information: Duplicate data can often lead to added costs, errors, and missed opportunities. Due to a proliferation of operating systems, duplicate efforts, and mergers and acquisitions, companies are saddled with duplicate records for customers, suppliers, products, and more.

- Time-consuming approval processes: The ups-and-downs and ins-and-outs of getting that approval stamp can sometimes take longer than necessary due to convoluted workflows or even inefficient time management.

- Excessive video calls or other forms of communication: There is such a thing as too much communication. If every single step of your process requires a check-in between multiple people, they're likely not making the best use of their time.

- Delay in response time: Response time is critical in avoiding the dreaded bottleneck effect. Having too much waiting time will inevitably cause delays and jam up your workflow.

- Unused resources: A waste of inventory presents a clear problem in terms of costs. Often, not having a clear panorama of your assets will result in unused resources and doubling up on expenditure (a good IT Asset Management solution, such as InvGate Asset Management, will go a long way towards alleviating this issue).

- Too many employees doing the same task: Redundancy is a huge problem in any organization, eating up your precious manpower, and resulting in decreased productivity. This is the ideal problem for process managers to identify and resolve.

- Outdated software: Keeping software versions updated and functional should be a priority for any process manager. A software asset management strategy is a great way to go about this.

10 process improvement methodologies you should know about

Before carrying out any process improvement plan, it is necessary to have a process improvement methodology. There are many takes on it out there, but the concept is basically the same: taking your old processes apart and finding ways to make them better and more efficient.

Below is a list of some of the most popular business process improvement methodologies.

1. Plan Do Check Act (PDCA Cycle)

PDCA stands for plan, do, check, act. It is also known as the Deming Cycle, developed by W. Edwards Deming, in the 1950s.

It is mainly used for the continuous improvement of business processes and it involves the following process improvement steps:

- Plan. The first step is to identify what can be improved in an existing process and carry out a plan or strategy to do so.

- Do. This refers to the action per se: implementing the change.

- Check. Once the change has been implemented it is necessary to evaluate if it has worked as expected.

- Act. Implement the change and see the plan through to completion.

2. Kaizen - or Continuous Process Improvement

Kaizen is a Japanese business philosophy that centers on continuously improving operations or business processes within a company. It is more of a mindset, and the idea is to foster members of the company (at all levels) to suggest and implement improvements within the organization.

Actually, Kaizen is a Japanese word that can be translated as a change for the better, or continuous process improvement.

This methodology includes:

- Identifying an opportunity or problem.

- Analyzing the process.

- Developing a solution.

- Implementing the solution.

- Checking if the solution has worked or if any adjustment needs to be made.

- Standardizing the solution.

All in all, Kaizen is an approach to creating continuous improvement based on the idea that small, ongoing positive changes can bring about significant improvements.

In order to think about the things that need to be improved and the processes to be implemented to achieve so, it is possible to hold a Kaizen event — which refers to a gathering of people involved in the process to be overhauled.

3. Total Quality Management (TQM)

Total Quality Management (TQM) is also a holistic approach as it seeks to involve the whole business organization in continuous process improvements that affects products, services, and the company culture itself.

Continuous process improvement means the ongoing improvement of products, services, or processes through incremental and breakthrough improvements.

These are the main aspects:

- It is customer-centered.

- It involves the whole company, all the employees. In this sense it's similar to the Kaizen approach: improvement efforts are shared across the organization.

- Communication is crucial to make sure everything runs smoothly.

- There's a strategic and systemic approach involved: quality is the main component here. The focus is always to improve the quality of the services and products offered.

- Integrated system: the horizontal processes that interconnect the various departments within an organization are a main field of interest for TQM.

- Decisions are based on data, facts .

- Continual improvement: it requires a proactive attitude to be continually looking for new opportunities of improvement.

4. Theory of Constraints

The Theory of Constraints (TOC) is a management philosophy which revolves around identifying limiting factors in a project. It was developed by Eliyahu M. Goldratt in "The Goal: A Process of Ongoing Improvement," published in 1984.

The main concept of the Theory of Constraints is that every process has a single constraint and that the total process can only be improved when the constraint is improved.

There are three main questions which are used as guidance in this methodology:

- What needs to be changed?

- What should it be changed to?

- What actions will cause the change?

The Theory of Constraints provides a specific methodology for identifying and eliminating constraints, referred to as the Five Focusing Steps:

- Identify the current constraint.

- Exploit the constraint (that is to say examine it to determine how to use it to its full capacity).

- Subordinate (meaning review all other activities in the process to make sure they support the needs of the constraint).

- Elevate (if the constraint hasn't been solved, then consider what other actions can be done to solve it).

- Repeat the whole process (this point wants to stress that there is a circular approach: once a problem is solved, people need to keep on looking for new opportunities of improvement).

The Theory of Constraints also includes a problem solving methodology called the Thinking Processes, which seeks to first identify the root causes of undesirable effects, which are referred to as UDEs, and then remove those UDEs.

5. Value Stream Mapping (VSM)

Value stream mapping (VSM) is a method for lean process improvement initiatives that focuses on the big picture first to then pinpoint the changes needed. It analyzes the current situation from a global perspective and sets out improvements to be made to complete the process. VSM is one of the pillars of lean management.

6. Kanban

Kanban is a management system that enables a visual representation of workflows, based on the Lean methodology, a way of optimizing resources, people and efforts in order to create greater value for the customer. The idea behind this is respect for people and continuous improvement.

Process Mapping is another key word here, as it implies using flowcharts to illustrate a process in order to identify opportunities for improvement.

Kanban helps better visualize the status of a process in a board with dynamic columns, representing different tasks and procedures. This visualization tool fosters visibility and therefore the possibility to come to solutions in a clear and effective manner.

The most usual representation of a Kanban methodology is a board with lots of post-its separated into three columns, each of which representing the following: tasks to be done/completed tasks and finished tasks.

7. Business Process Management

Business process management (BPM) refers to the methods used to discover, analyze, and optimize business processes. Nowadays it usually includes technologies to automate various tasks in order to have a more efficient performance.

Business process management activities can be grouped into the following categories:

- Design: Includes the identification of the existing process and the design of upcoming processes, ensuring a correct and efficient new design.

- Modeling: Takes the theoretical design and introduces combinations of variables (such as changes in costs, material shortages, changing of circumstances, etc.).

- Execution: Either human-driven (manual business processes) or software-driven (automated business processes), this part of the BPM lifecycle deploys the processes as designed and mapped out.

- Monitoring: Encompasses the tracking of individual processes, allowing statistics on the performance of the process to be provided. Also tracks the different states of an order.

- Optimization: Retrieves process performance information from modeling or monitoring phase, identifying potential bottlenecks and opportunities for improvement and cost-saving.

- Re-engineering: Once a process has become too unwieldy or inefficient, the process lifecycle can be fully re-engineered from scratch.

8. Six Sigma

Six Sigma is a statistical-and data-driven process that works by reviewing limit mistakes and/or defects. In terms of process improvement, it is a management ideology that focuses on statistical improvements to business processes while also advocating for qualitative measurements of success over qualitative markers.

There is a heavy presence on statistics and financial analysis in the Six Sigma approach to process improvement. It relies on these statistical benchmark to show how well (or otherwise) a business process works, examining what causes errors and when these errors produce defects (a defect is considered anything that is produced outside of consumer satisfaction). The goal is to reduce manufacturing defects to no more than 3.4 occurrences per million units or events.

9. Lean Manufacturing

As the name implies, Lean Manufacturing is a production method focusing on process improvement for manufacturing. Its main goal is to reduce times within the production system as well as response times from suppliers and customers, trying to match production to demand by only supplying goods that have been ordered. It focuses on efficiency and productivity as well as reduction of waste.

Lean Manufacturing focuses on reducing cycle flow by eliminating parts of the process that don't add any value either to the customer or the supplier of goods. While this may all conjure up images of a factory line, the concepts in Lean Manufacturing can also be applied to areas outside of manufacturing, such as customer service, marketing, or more.

The use of the term "Lean" to refer to this manufacturing approach was coined by American businessman John Krafcik in 1988, and it was further defined by researchers James Womack and Daniel Jones as consisting of these key principles:

"Precisely specify value by specific product, identify the value stream for each product, make value flow without interruptions, let customer pull value from the producer, and pursue perfection."

10. Whys Analysis

You know how kids get to a certain age where "Why?" seems to be the single most important question in their minds? Well, they may be on to something. Whys Analysis (or The 5 Whys Technique, as it is sometimes called) is a method invented by Japanese industrialist Sakichi Toyoda. This quickly became an integral part of his company's manufacturing principles, and became part of the Lean method.

“The basis of Toyota’s scientific approach is to ask why five times whenever we find a problem … By repeating why five times, the nature of the problem as well as its solution becomes clear.“ - Taiichi Ohno

Sound simple, right? There's actually a little more to it than just asking "why" five times, but that's a great starting point. Getting to the core of the problem via this root cause analysis and including people with strong, practical experience on the topic allows managers to inspect problems in depth therefore improve their business processes.

Automation and process improvement

Identifying opportunities for automation and using a tool to implement them are key parts of process improvement, to enhance efficiency and deliver fast solutions. The first step is to find the automation software needed and the processes that should be automated to achieve the desired results.

Choosing a workflow management software with ITSM automation capabilities will reduce redundancies and help make a more effective use of resources. Automation solutions can carry out repetitive and tedious tasks, and therefore allow the human beings who usually perform those tasks to focus on more creative activities, which can not be done by machines.

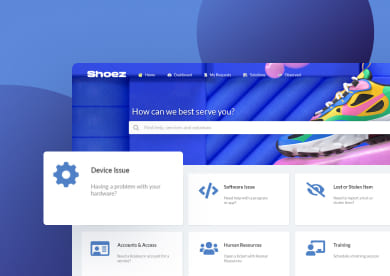

Besides, using automated solutions for certain repetitive tasks will also reduce the number of errors made. It will help eliminate waste in terms of mistakes, time and costs. InvGate Service Management is a fantastic ITSM software solution that includes a robust workflow builder with automation capabilities, allowing IT leaders to easily manage requests across the organization.

Lastly, automated software can provide business members with a clear oversight of the situation as a whole, it will include real time analytics and other elements to better identify any problem or incident which may need to be solved or process to be improved. All in all this will lead to incremental improvements.

Lastly, automated software can provide business members with a clear oversight of the situation as a whole, it will include real time analytics and other elements to better identify any problem or incident which may need to be solved or process to be improved. All in all this will lead to incremental improvements.

Frequently asked questions

What are process improvement efforts or activities?

Process improvement efforts are any initiative or activity that aims to improve business processes. The idea is that process improvement leads to more effectiveness and efficiency.

What are some examples of process improvement?

It refers to areas that need to be improved. For example: a business may seek to reduce costs. The idea would be to identify areas where maybe there is more waste or resources are not being adequately used. A thorough analysis to save cost could help identify that the organization is buying more perishable items than needed, or is over using space to store inventory that is not used.

Another example of process improvement could be the need to increase revenue. In order to achieve this objective, members may decide to introduce new marketing techniques, get rid of products that are not selling well or produce different services to cater for the needs of the clients.

What is process change in an organization?

Process change within an organization refers to the actions a business undertakes to adjust a component of its business. This could include external or internal processes, corporate culture, infrastructure or any other aspect.

What is process mapping?

Process mapping refers to the use of a process map as a planning and management tool that helps visualize the flow or work. It involves different steps: The first step is to identify the problem, then ideas are brainstormed, and a sequence of steps are figured out. Then a flowchart is drawn using this input. After a thorough discussion of the situation and steps to be taken the process chart is completed.

.jpg?upsize=true&upscale=true&width=780&height=205&name=how-to-create-a-service-level-agreement%20(1).jpg)