An equipment maintenance log is a centralized record that captures all maintenance and repair activities to ensure assets, whether they are machinery, vehicles, facilities, or IT equipment, operate safely and efficiently.

By tracking key details like service dates, tasks performed, parts replaced, and associated costs, this log helps organizations reduce downtime, extend asset lifespan, and move from reactive fixes to more proactive or even predictive maintenance strategies.

Maintenance logs can take many forms depending on the type of asset and the level of detail required, but they all start in the same place: documenting essential asset information. In this blog post, we’ll walk through that first step and every other component that a well-structured equipment maintenance log should include.

What is an equipment maintenance log?

An equipment maintenance log is a structured record that tracks the upkeep, repairs, and scheduled maintenance of assets. A complete log, also known as an equipment maintenance log record, combines two essential components: basic asset data (name, model, serial number, and location) and a chronological history of every maintenance, repair, or inspection, including who performed it and the cost.

Although each organization can develop its own log based on specific needs, many start with an equipment maintenance log template tailored to their industry and goals. Paper forms and spreadsheets remain common but are prone to errors and inconsistencies.

More mature teams now maintain these logs within IT Asset Management (ITAM) platforms, which centralize information, automate schedules, and offer real-time visibility into asset health to stay proactive instead of reactive.

Types of equipment maintenance log

Choosing the right type of equipment maintenance log is essential to building a maintenance history that is accurate, useful, and actionable. Each log serves a different purpose, so selecting the right one helps organizations understand asset behavior, optimize interventions, and support better long-term decisions.

#1: Preventive maintenance log

This equipment maintenance log tracks scheduled tasks designed to prevent failures before they occur. It typically includes software updates, security patches, hardware checks, and other routine activities that help reduce downtime and extend asset lifespan.

#2: Corrective maintenance log

This equipment maintenance log documents repairs performed after an issue has already been detected. Although reactive, a clear corrective log helps teams identify recurring problems and strengthen long-term resolution strategies.

#3: Predictive maintenance log

This equipment maintenance log is used in data-driven environments where maintenance is triggered by real-time performance indicators. IT teams rely on monitoring, analytics, and AI to predict issues and service assets only when needed.

#4: Asset lifecycle maintenance log

This equipment maintenance log tracks the full history of an asset from acquisition to disposal. It supports planning for upgrades, replacements, and decommissioning with clear historical context.

#5: Compliance maintenance log

This equipment maintenance log ensures all maintenance activities meet regulatory, legal, and industry standards. It is essential for organizations in highly regulated sectors like healthcare, finance, and manufacturing.

#6: IT-specific maintenance log

This equipment maintenance log focuses on hardware and software upkeep, including patching, server maintenance, firmware updates, and network checks. Many teams integrate it into ITAM platforms to automate tracking and reporting.

How to create an equipment maintenance log in 6 steps

Before outlining the steps, it’s important to clarify what you’ll be building. A standard equipment maintenance log template always includes two core blocks, regardless of industry or asset type: general equipment information and a chronological record of maintenance actions.

The following process will help you structure both parts in a clean, consistent, and useful maintenance history.

1. Identify the assets to track

Start by listing the equipment, hardware, or IT assets that require maintenance. This may include servers, laptops, network devices, software applications, or any critical infrastructure. Assign each asset a unique identifier, such as a serial number or asset tag, to avoid confusion.

2. Choose a logging method

Decide where you’ll keep the maintenance log. Paper records or spreadsheets may work temporarily, but they quickly become difficult to manage. Centralized software, ideally integrated with ITAM processes, makes tracking easier and enables better visibility across teams.

3. Define key information to include and create equipment maintenance log template fields

This step is essential because the maintenance log fields you define determine the clarity and usefulness of your entire maintenance history. To build a reliable equipment maintenance log template, make sure to include:

- Asset details: name, model, serial number.

- Maintenance type: preventive, corrective, predictive, or compliance-related.

- Scheduled maintenance dates: upcoming service intervals or deadlines.

- Performed maintenance and repairs: description of work completed.

- Assigned personnel or technician: who performed the task.

- Costs associated with maintenance: parts, labor, or service fees.

- Asset status: active, under maintenance, or decommissioned.

4. Set up a maintenance schedule

For preventive maintenance, establish a schedule based on manufacturer guidelines or performance monitoring. If using an ITAM system, set automated alerts to notify teams when maintenance is upcoming or overdue.

5. Log maintenance activities consistently

Record every update, repair, or inspection as soon as it happens. Missing or delayed entries lead to gaps that can cause downtime, compliance issues, or duplicated work. ITAM platforms can automatically update the log when related tickets are completed.

6. Monitor and optimize the process

Review maintenance logs frequently to identify patterns, recurring issues, or assets that may need replacement. These insights allow IT teams to adjust schedules, improve workflows, and make better long–term decisions.

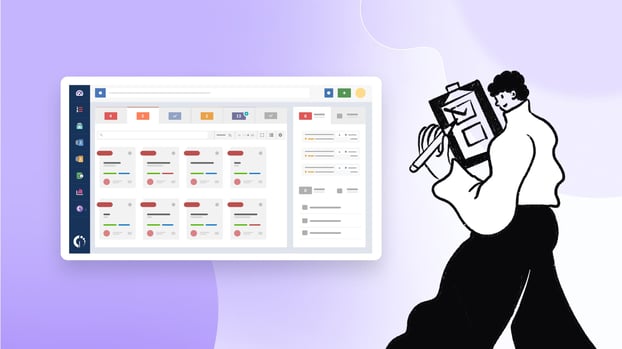

Automate equipment maintenance logs with InvGate Asset Management

InvGate Asset Management automatically captures all activity related to an asset, including every maintenance action performed. This information is stored in the asset’s Activity tab, where it can be filtered to display only maintenance-related events, making your maintenance history easy to review and audit.

The platform also includes flexible features that help you implement and enforce your maintenance policies -and any other IT Asset Management policy- with precision. Key capabilities include:

- Health rules: define what “healthy” means for each asset and trigger automated actions when conditions fall outside those thresholds.

- Automations: streamline maintenance tasks, including automatically updating the “last maintenance date” field when work is completed.

- Smart tags: identify assets approaching their maintenance date so teams can monitor them more closely.

- QR codes: generate QR codes to quickly access, update, and track all relevant asset information on the spot.

Ready to simplify and automate your equipment maintenance logs? Start your 30-day free trial of InvGate Asset Management or contact our sales team to see how it fits your organization.